Electrical Infrared Inspections

Introduction

Today’s electrical systems are complex and require someone with the proper expertise and electrical background to diagnosis issues most effectively before they turn into more costly failures.

Excessive heat relative to the rest of the system can be a sign of potential problems. These higher temperatures often indicate loose or faulty connections, improper wiring installation or prior failures in electric equipment. It is often difficult to determine if there is a ticking time bomb within your electrical system simply from a visual inspection. Certified Infrared can work with your facility to satisfy your insurance requirements and help pinpoint electrical problems before they fail. Ultimately an electrical infrared inspection can reduce your operational downtime and keep your operations running smoothly.

At the completion of each electrical inspection survey, a comprehensive report will be provided documenting all issues and items inspected.

How do we find issues using thermal imaging?

We find issues in electrical systems by looking at the source of the thermal energy relative to the energy dissipated through a device. We have the expertise to understand what should be hot and what should not.

Fortunately, the major of commercial power systems use 3 phase power and provides an easy reference point for review. A 10-degree rise is perfectly normal on a loaded circuit; however, a 10 degree rise on one leg of an equally loaded breaker indicates an issue.

Our technicians also work to isolate the exact source of the heat. Normally loaded circuits equally distribute the thermal loading through the circuit.

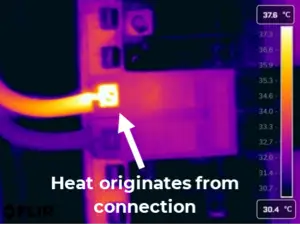

Anomalies, such as loose connections, will have a concentrated heat source where the compromised connection is.

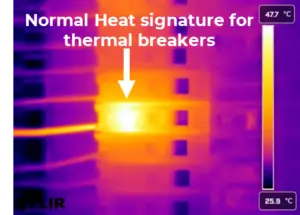

For Example the breaker on the left produces a thermal heat signature consistent with a normal operating breaker. The breaker on the right however does have an issue, even though it is cooler then the breaker on the left. Notice how the heat source is focused on the wire termination. This issue can likely be fixed with a few turns of a screwdriver.

Our expertise allows us to pinpoint issues to reduce the scope of repairs to the actual failure point. Why replace an entire panel for only a loose connection?

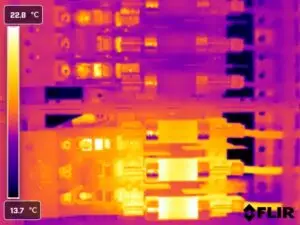

Having the experience, training and education allows our technicians to understand the circuitry involved in your critical systems. We are familiar with the heat signatures of normally operating equipment. For example, equipment such as relays, control circuitry, switching power supplies, transformers, etc. are designed and expected to run at elevated ambient temperatures.

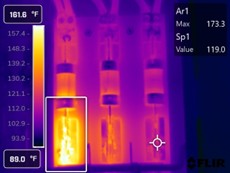

The set of fuses on the left, even though shows an elevated heat signature, depicts a normal operating condition. Notice how heat is evenly distributed across the fuse and all connection points. The thermogram on the right however, indicates an issue, heat is concentrated to the fuse clip. Loose clips are a common failure point of fused connections.

Each technician looks at thousands of pieces of equipment each year and is trained to identify critical and non-critical issues. Each anomaly is noted with a rating based on it’s severity. Because we function as an independent inspection agency we only report actual issues. We do not service any of the equipment we inspect and are not creating business for ourselves by filling up a report unnecessarily.